Electric motor current analysis test

Alvand Sanat Javid Alborz company, in addition to repairing all types of electric motors and electric machines, provides current analysis services for condition monitoring, maintenance and timely repairs. The flow testing team of Alvand Sanat Javid Alborz company is placed next to the maintenance and repair team located in the factories, and by performing rotating inspections, it continuously evaluates and analyzes the condition of the machines and informs the maintenance and repair team about the condition of the equipment.

Alvand Sanat Javid Alborz company monitors the behavior of these machines by implementing a comprehensive system of technical inspection of electric motors and provides timely maintenance and repair solutions by focusing on the parts that show the initial signs of failure.

Alvand Sanat Javid Alborz Group, while monitoring the correct operation of electric motors and predicting the machine’s behavior with various techniques, aims to minimize the unsightly exit of the industrial unit caused by faults in the rotating machine components. It should be noted that the analysis of electrical effects and electromotor power is considered the main and most fundamental component in condition monitoring services.

This test includes the entire electrical system from the input of the power switch in 10 kV, 6 kV, 600 V and 400 V panels and ends with the most detailed parts of the electric motor. The drive system, cables, stator winding, rotor cage (for squirrel cage rotors) and rotor winding (for coiled rotors) will all be monitored and defects that cannot be detected by other tools until damage is caused. In this inspection, they will be identified in the very early stages.

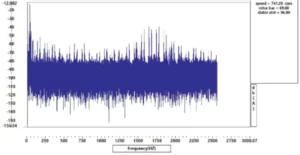

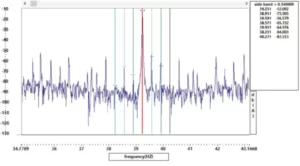

Defects such as breaking or cracks in the load rotor, improper connection of the load rotor or defect in the core, air gap, lack of centering of the rotor, unwanted permanent or momentary harmonics in the voltage, end ring and current, half-burning of the rectifier and inverter system in the drive, voltage shaft and leakage current, partial discharge in prone coils, torsional vibrations, are all defects that, despite them, the electric motor will continue to work for a limited period of time under tension and without external effects, but it will suddenly stop causing extensive damage. . Interestingly, all these defects can be identified before causing damage with the exclusive technique of analyzing electrical effects.

The electrical effects analysis technique implemented by Alvand Sanat Javid Alborz is low risk and low cost. With this technique, it is possible to detect defects such as broken and cracked rotor rods, dynamic and static eccentricity, bearing failure, unbalance, misalignment, foundation laxity, and mechanical and electrical defects of the engine.

The method of performing electrical effects analysis

The analysis of electrical effects of Alvand Sanat Javid Alborz Company is a process in which the signals of supply voltages and currents, signals of leakage currents and voltages, and signals containing partial discharge of the motor are collected in order to diagnose and root out various defects and in a database. are saved for reference. Then the result of the analysis will be compared with the initial tests that are called immediately to show the presence of any type of problem in the device. Electrical effects analysis systems are in the form of ONLINE electrical effects analysis, in which there is no need to remove the machine from the circuit, but the whole process is done while the machine is working.

Vibration analysis and its importance

One of the most important control items in monitoring the electrical and mechanical condition of rotating equipment and reciprocating equipment is the vibration analysis of this equipment. In these investigations, a wide range of electrical and mechanical cases such as rotor condition, drive and remote control system error, imbalance, misalignment or misalignment of shaft and coupling, resonance, looseness, foundation defects, bearing defects, cavitation, etc. Their defects can be identified in the early stages.

Interestingly, bringing the vibrations of a machine to the permissible limit and keeping it within the standard range set by the equipment manufacturer can increase the life of the machine by 70%. During periodical inspections of equipment vibrations, the vibration values of each machine should be taken periodically and analyzed and the results of certain components should be compared with the values of the previous inspection period. When the device has high sensitivity, its vibration behavior should be controlled instantly and online. In this case, by running the online vibration analysis system, you can take control of the car and prevent its breakdowns and sudden stops. The online protocol of the vibration control and analysis system is compatible with all standard and current protocols in the industry.

Ultrasonic inspection and its effects

In the field of condition monitoring, ultrasonic inspection is newer than vibration analysis. Although this type of troubleshooting in medicine is much older than this. Currently, the ultrasonic technique in the field of condition monitoring is able to detect the failure of rolling bearings, collision, failure of gears and so on. . . .

Bearing defects in the very early stages that cannot be detected by vibration analysis are identified with this technique and corrective measures will be taken before the bearing condition becomes acute. According to the investigations, 36% of the bearing defects are related to excessive greasing. The presence of more than necessary amount of grease in the bearings will increase the temperature of the bearing, liquefy the grease and eventually damage the bearing.

Also, 34% of bearing defects are caused by applying double load to the bearing, which is caused by misalignment or imbalance of the rotor. 4% of the defects are caused by contamination of the lubrication system. All of these can be detected by ultrasonic inspection before they lead to bearing damage.

By identifying and solving these problems before the bearing failure, it is possible to prevent double pressure on the repair personnel, which is caused by changing the bearing, including opening and closing, disassembling the rotor, as well as re-centering it, and save time and money.

Alvand Sanat Javid Alborz Company provides the following services in the field of equipment flow analysis testing:

Detection of internal leakage of valves, compressed air, early detection of rotating equipment failures, diagnosis of lubricant problems and diagnosis of arc and corona.

How to plan for technical tests and analysis

Alvand Sanat Javid Alborz Company, based on the variety of power equipment and rotating equipment, their class and power, and based on the suggestions of reliable manufacturers, determines the weekly, monthly, bi-monthly, seasonal, six-monthly, and… and implements.

The results of the flow analysis test of each system are reviewed and entered in the database of equipment records. The reports of the next courses will be automatically matched by the software with the results of the previous flow analysis tests that are included in the mentioned equipment file, and finally the necessary reports will be issued.